Stainless Steel is a sub-category of alloy steels, that contains miniumum 10,5% Chromium (Cr) content.

Chromium produces a thin, passive and self renewable layer of chromium oxide on the surface of the steel. This layer prevents any further corrosion on the inside or the outside of the surface. This property is what distinguishes stainless steel from other steels.

Discovery of the stainless steel goes back to early 1900's in Sheffield, England. Then the development of the stainless steel spread in Germany and France. Even though duplex grades were developed in the 1930's, typical duplex grades were mastered in the 1970's.

Stainless steels typically contain Iron (Fe), Chrome (Cr), Carbon (C), Silicon (Si), Manganese (Mn) and usually Nickel (Ni). Stainless steel grades vary in properties, with the addition or removal of Chrome (Cr), Carbon (C), Nickel (Ni), Molybdenum (Mo), Silicon (Si), Manganese (Mn), Copper (Cu), Titanium (Ti), Sulfur (S), Niobium (Nb) and other elements.

Stainless steels may be used in low and high tempratures. They are resistant to corrosion and oxidation. Standard stainless steel grades are heat resistant up to 700°C. In grades with increased Nickel (Ni) ve Chrome (Cr) content, heat resistance is increased up to 1150°C.

Due to their formability, they can be used for many different applications. Due to their durability, they have a very low total life cycle cost. Even though they are more costly than carbon steels, stainless steels need low or no maintenance and they are much longer lasting. Therefore in the long run, stainless steels are more economic than carbon steels.

Stainless steels are comparatively very hygenic. In medical industry, food & beverage industry, kitchen equipments, home appliances and similar industries, stainless steel consumption is almost indispensible.

Stainless steels are aesthetically appealing. They are environmental friendly and 100% recyclable.

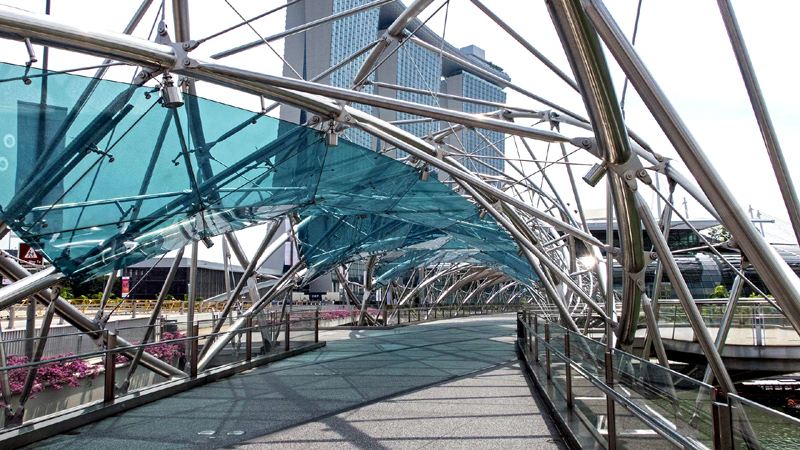

(Images: Duplex stainless steel bridge, Helix Bridge Singapore)